Liquid Metal milestones

-

![]()

July 2022

First in-house batch of GaInSn: we “cooked” the alloy in house as in “Breaking Bad”. This is the same material found in your mercury-free thermometer, in ml quantities, but we cooked tens of liters, in a brewery pot.

-

![]()

October 2022

Our first table-top liquid metal loop, built with parts from “Leroy Merlin” (a European “Home Depot”).

-

![]()

February 2023

Our first liquid metal pump built in-house, by arraying permanent magnets on a rotor, with a whooping 110 kW maximum power.

-

![]()

March 2023

Largest GaInSn loop in the world: 7m long, 1 m/s flow (“Skyfall 0”).

-

![]()

July 2023

First levitation of a liquid metal flow (1-2 cm thick) in a meter-sized cylinder by electromagnetic forces (“Skyfall 1a”).

-

![]()

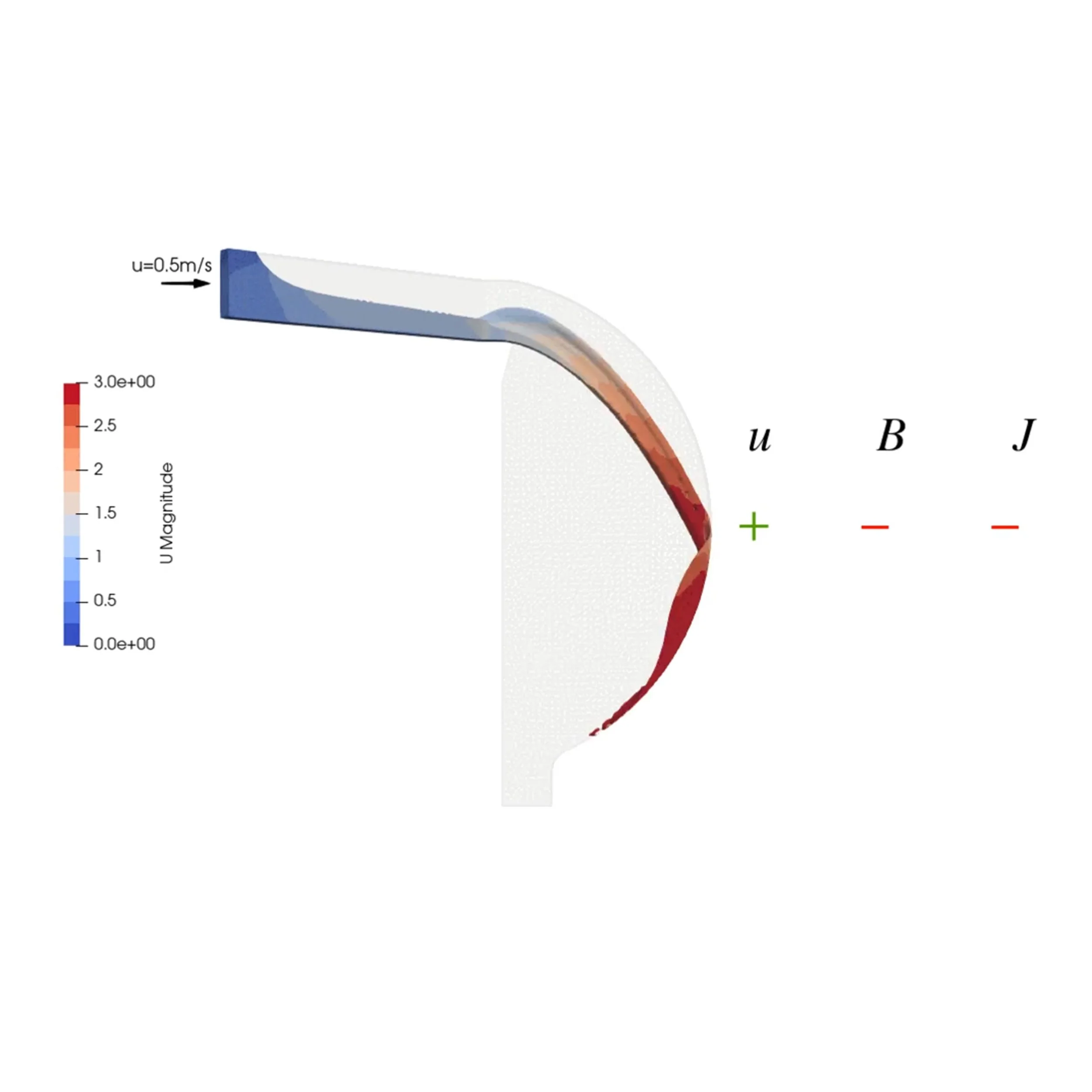

December 2023

Completed our in-house 3D free-surface Liquid Metal (LM) Magnetohydrodynamics (MHD) code and successfully benchmarked it against experimental results. Now regularly used to predict and interpret LMMHD experiments.

-

![]()

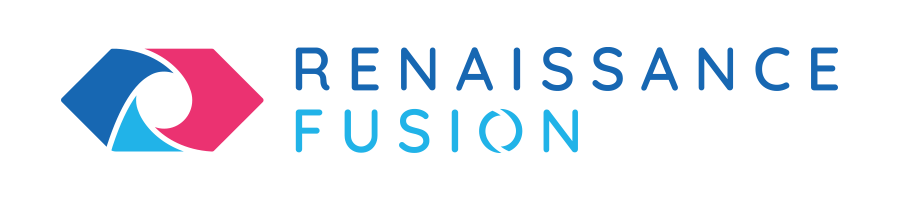

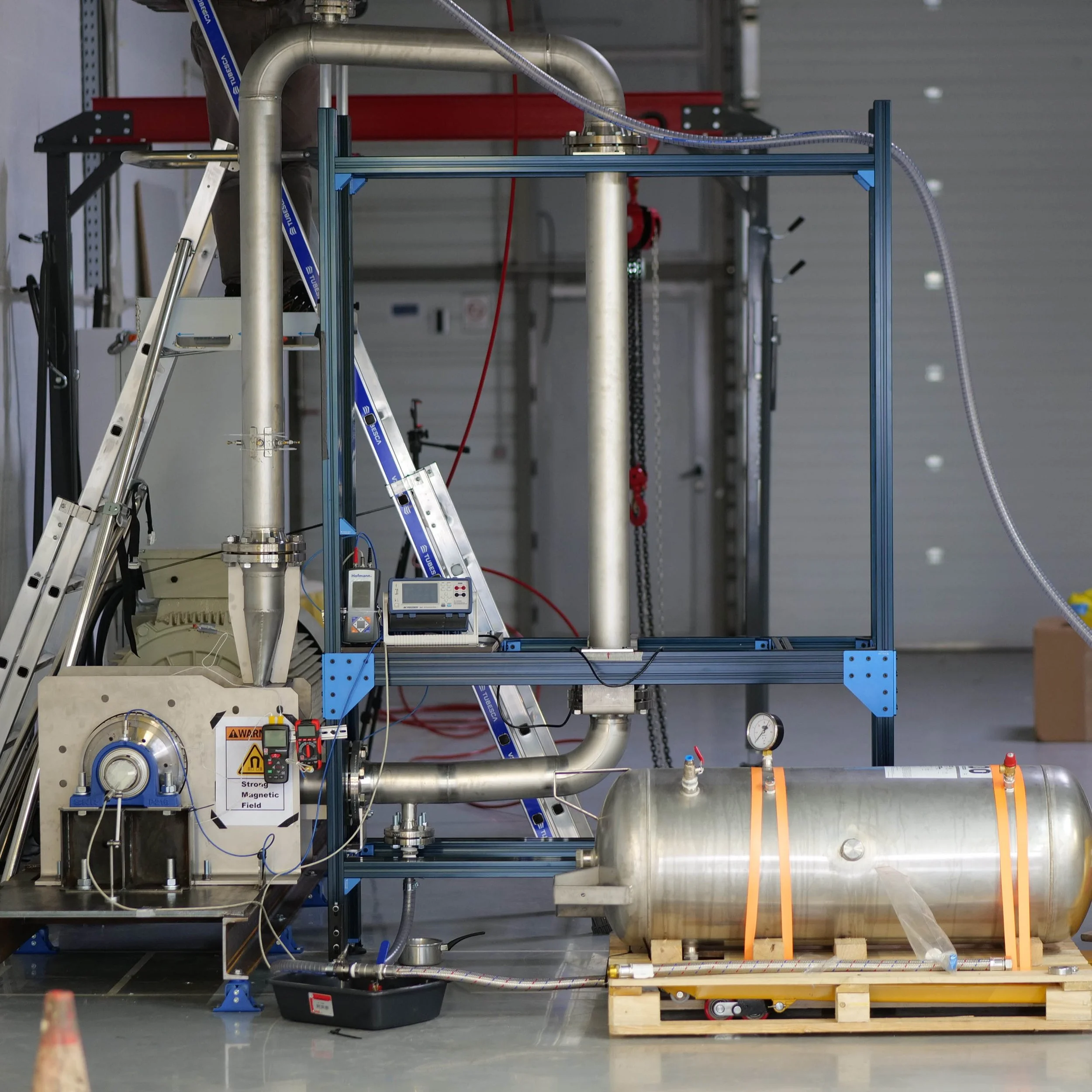

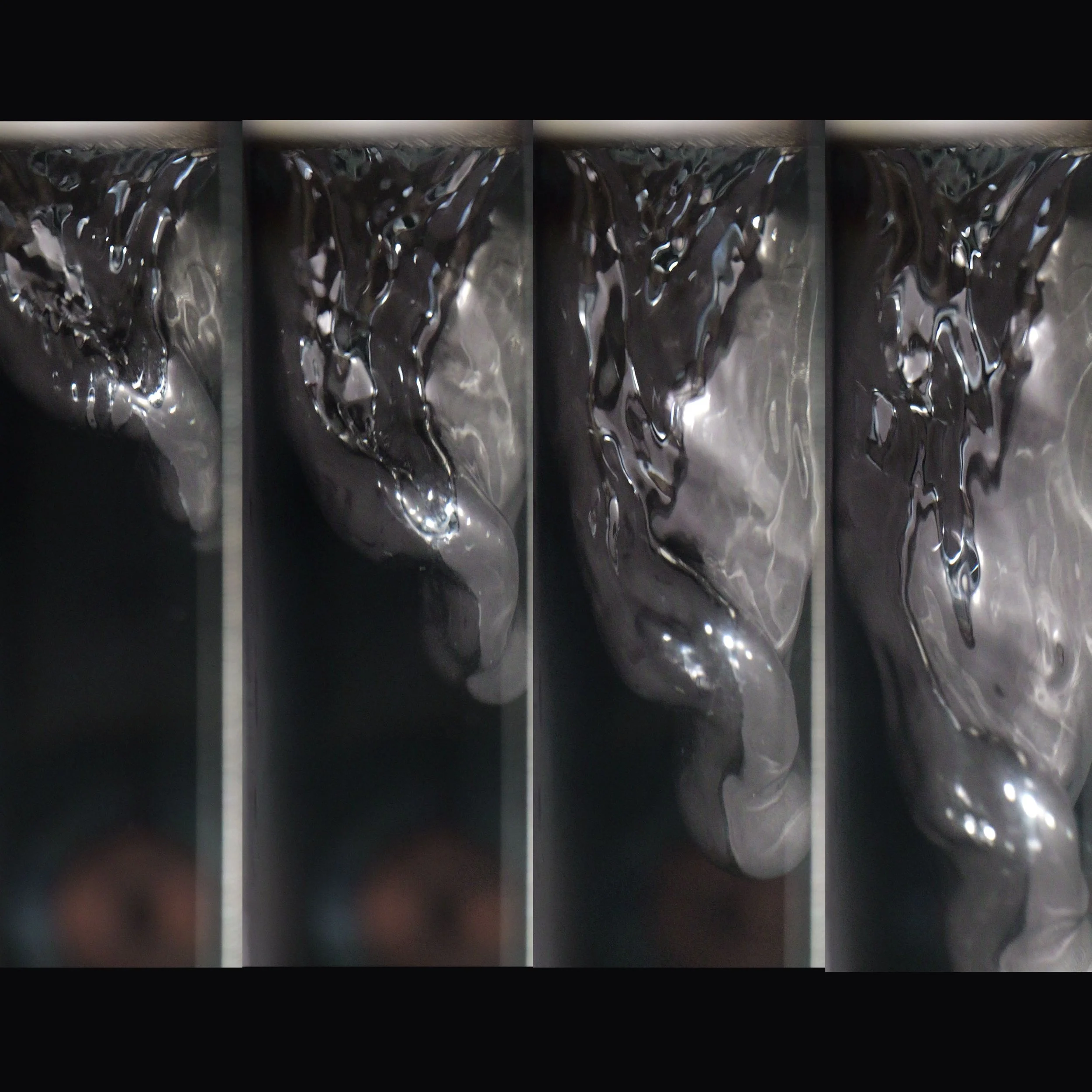

February 2024

First levitation and control of a very thick liquid metal flow in a cylinder. The cylinder diameter (1 m) approaches reactor scales, and the flow thickness (10 cm of GaInSn, equivalent in mass to 120 cm of Li-LiH) exceed by 3.5x our reactor needs. Compared to Skyfall 1a, we also greatly reduced the fall of droplets that could radiatively collapse the plasma (“Skyfall 1b”).

-

![]()

March 2025

Identified two “finalist” solid materials that will withstand dynamic corrosion by hot liquid metals in our stellarator reactor (only few microns per day).

-

![]()

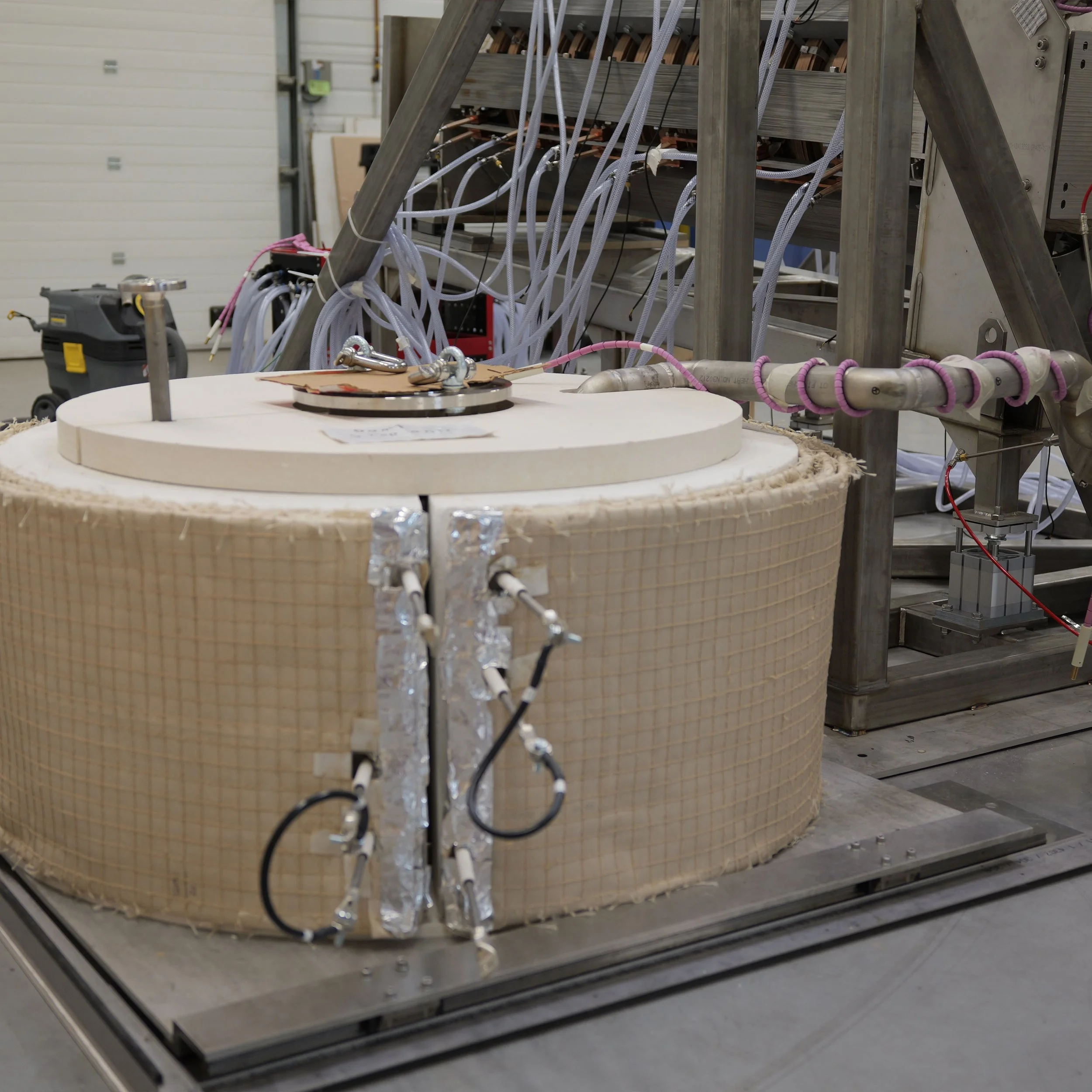

May 2025

Completed our first large Annular Linear Induction Pump (ALIP) for hot Sn, Li and other metals – the first company and one of only 2-3 organizations worldwide to ever build and ALIP of that scale and the first one, ever, capable of operating at up to 850 C.

-

![]()

June 2025

First successful test of a proprietary “freeze valve” to stop the liquid metal flow by rapid solidification.